RESPONSIBILITY FOR SAFE DELIVERY OF SHIPMENT

Every shipment is inspected and checked out at the MARKETEER factory before being turned over to the transportation company which makes delivery. The responsibility for safe delivery rests with the transportation company, except in cases where MARKETEER provides its own carrier.

To make sure that the shipment is delivered to you in good condition and in accordance with quality shown on Invoice or Packing Sheet, it is important that you check the shipment immediately upon arrival. If there is any shortage or damage, request the Freight Agent to note it on both the Delivery Receipt and the Freight Bill.

If you accept shipment from the transportation company short of what is enumerated on the Invoice or Packing Sheet, or in damaged condition , without having proper notation made by the Freight Agent, you do so at your own risk.

If bundles and crates are in APPARENT good order on arrival, but, on opening, contents are found to be damaged or incomplete, call the Freight Agent or Adjuster to inspect same and have him mark such concealed damage or loss on the Freight Bill. THIS MUST BE DONE WITHIN 15 DAYS AFTER DELIVERY. Save ALL packaging material until freight company inspection is made.

Since the responsibility for safe delivery is assumed by the transporting agent, except when MARKETEER provides its own carrier, claims for loss or damage on the shipment must not be deducted from our invoice, nor payment of the invoice withheld pending adjustment of such claims.

We will be glad to assist you in every possible manner in collecting claims for loss or damage during shipment, but this willingness on our part does not make us responsible for filing or collecting claims or replacing materials.

HOW TO ORDER REPLACEMENT PARTS

Your MARKETEER electric vehicle is very easy to operate, service and maintain. It has few parts to wear out or replace. All parts are easily accessible and fundamental parts are demountable.

Replacement parts are available through your local dealer or will be shipped directly to you from the MARKETEER factory the same day your order is received (almost without exception). When a part of your MARKETEER car needs to be replaced, please make use of the Parts List section in the back of this booklet. By referring to the pictures of the various assemblies, you can identify the needed part and its part number. When ordering, always give the quantity needed, the part number and the description of the part. EXAMPLE:

Please send (1) one, Part No. 31-000-00, Feed Hopper, complete

(1) one, Part No. 80029, Battery Filler

(2) two, Part No. 30-002-04, Cover Hose, Roller Guide

This will eliminate the possibility of misunderstanding.

All parts will be shipped C.O.D., unless other arrangements have been made. Prices are subject to change without notice. Concerning a part or service not covered in the Parts List section, such as repainting etc., please contact your dealer or MARKETEER directly. We will be most anxious to be helpful to you. All parts in this catalog are subject to change, with improved versions. On all orders, the latest model part which is interchangeable with the original equipment, will be sent.

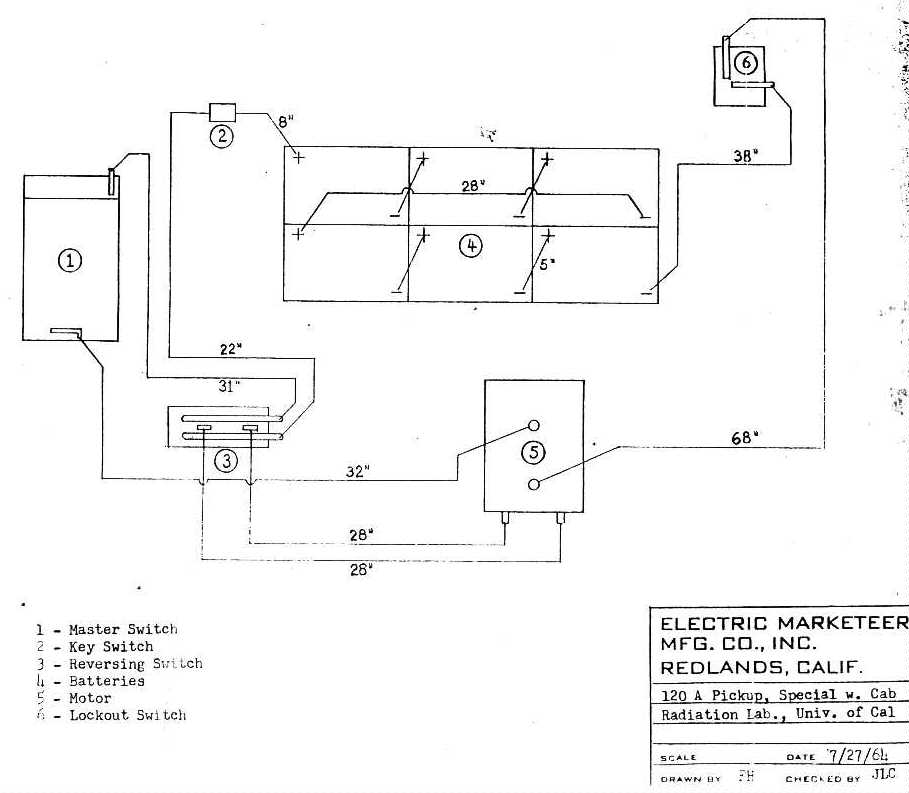

SWITCHES.

The Master Switch should be kept clean, but NEVER greased. The brush is impregnated with Graphite and supplies all the lubrication needed.

The FORWARD/REVERSE and Par-Ser Switches should be kept clean and greased with light bearing grease.

MOTOR BRUSHES.

Check motor brushes every three months. New brushes will be required occasionally. If the car does not have good pick-up and runs sluggishly, it may be a sign of worn motor brushes. If the bad connection cased by a worn brush has caused arcing and overheating, the brush tension spring may also need replacing, because overheating may cause it to lose its tension. Also, the motor armature commutator segments may need smoothing with extra fine sand paper.

TIRES.

Keep tires at 30 lbs. Pressure. Low pressure in tires decreases the distance the car will operate on one charge.

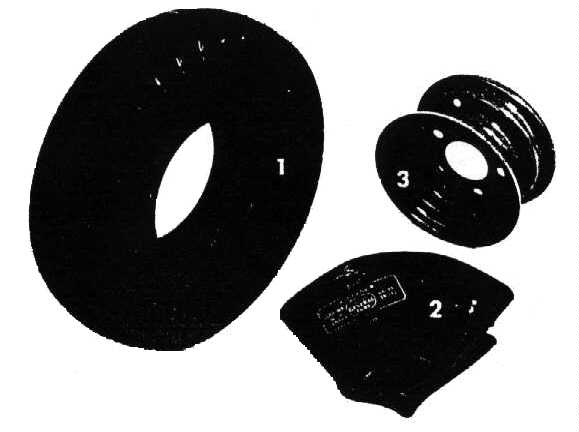

CHANGING TIRES.

These vehicles are equipped with either Drop Center Rims or two piece Split Rims. Remove wheel from hub and then remove tire from wheel according to the type of rim you have.

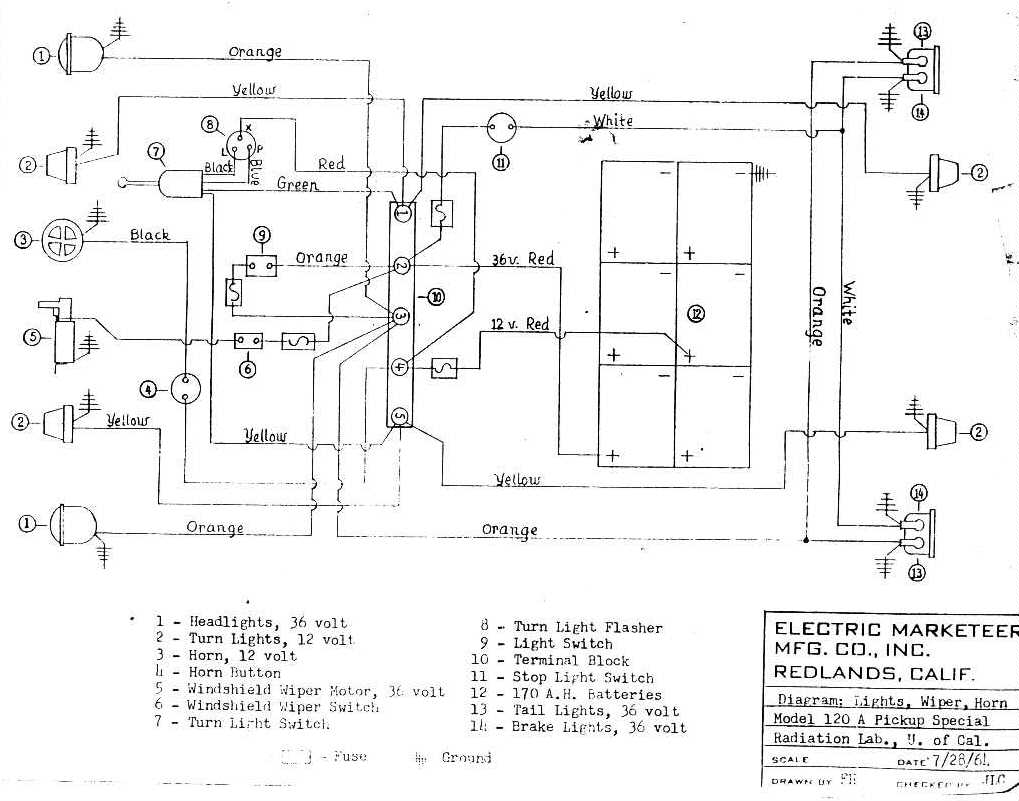

LIGHTS.

The Head and Tail Lights are connected to the 36 Volt system. When the vehicle is in Series (or fast speed) the lights will shine brightly; when the vehicle is in Parallel (or slow speed) the lights will shine dimly. This is normal.

GUARANTEE.

The motor is guaranteed for one full year.

All guarantees are at the factory.

All products of our manufacture are guaranteed for 90 days from the date of purchase against defects in material or workmanship. All products of other manufacturers are subject to their own warranty. Misuse and abuse, natural wear and tear are expressly excepted.

Parts or material to be replaced must be shipped prepaid and subject to our examination. Specifications, dimensions and prices are subject to change without notice.

The batteries are guaranteed for 12 months on a use basis. If the batteries are more than 6 months old, we replace all the batteries in the vehicle at the same pro rate when one or more needs to be replaced, even though not all are defective. The reason for this is that it is important to keep all the batteries at the same age.

If you write in about your MARKETEER be sure to mention the serial number on the motor and dash. This number is identical with the number on your invoice.

WARNING !

NEVER tow or push your electric MARKETEER with an automobile.

CARE OF BATTERIES.

BRAKE ADJUSTMENT.

The Service Brakes on your Truck are standard automotive type brakes. Follow the same procedure for adjustment as you would on an automobile.

BRAKE RELINING.

Follow standard automotive practice to reline the service brakes.

PLACES TO GREASE AND OIL.

Alemite grease fittings are located on:

Spring Shackles

King Pins

Steering, Brake and accelerator Linkages

All wheel bearings should be hand packed about once a year. Remove wheels for this operation.

Check Differential every six months. Add 90 weight oil as needed.

Light Oil should be put on all other pivot and linkage points that do not have grease fittings.

REPLACEMENT of CHAIN and SPROCKETS

Refer to M-200 Drive Unit Picture

WARNING: Before doing any work on your truck, always turn the key to the OFF position. Always remove one battery wire to prevent accidents from short circuits. DO NOT wear a ring or wrist watch.

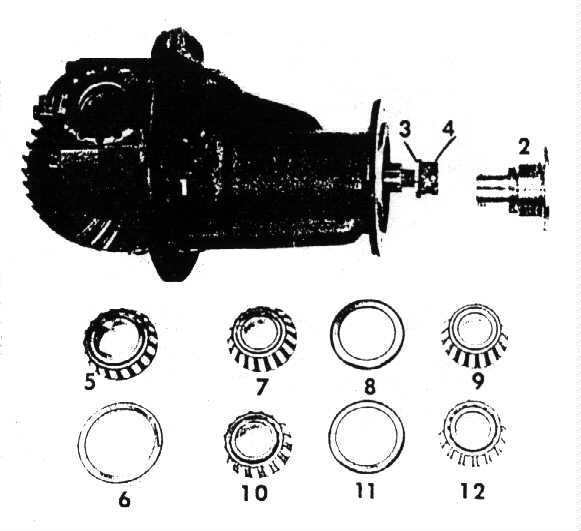

DIFFERENTIAL

(used with M-100 and M-200 Drive Units)

|

Item |

Part. No. |

Description |

Quantity Used |

|

1 2

3 4 5 6 7 8 9 10 11 12 |

10-051-00 10-002-08

10-002-09 10-002-07 10-002-06 10007 10017 10167 10197 10187 10077 10087 10207 |

GEAR SECTION, Differential M-100 FLANGE, Sprocket, used on M-100 Drive with 1 Sprocket shown in Picture FLANGE, Sprocket, used on M-200 Drive with 2 Sprockets not shown in Picture WASHER, Flat, 3/4" I.D. x 1-1/2" O.D. NUT, Hex, Slotted, 3/4-16 BEARING, Carrier, # 25580 RACE, # 25520 BEARING, Inner Pinion, # HM 89446 RACE, Pinion Bearing, # HM 89410 BEARING, Outer Pinion, # HM 89443 BEARING, Inner Pinion, # 31593 RACE, Pinion Bearing, # 31520 Bearing, Outer Pinion, # 31590 NOTE: In some Differentials items 7, 8 and 9 are used, while in others items 10, 11 and 12 are used. Please check before ordering. |

1 1 1 1 2 2 1 2 1 1 2 1

|

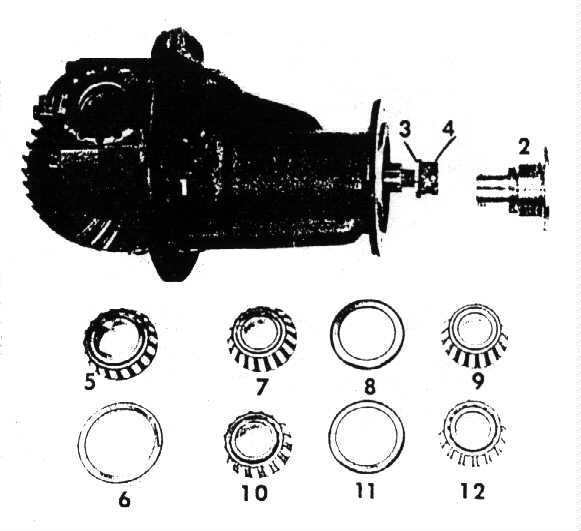

M-100 DRIVE UNIT

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

|

10-051-00 17-050-00 10-052-01 20093 10-052-03 10-052-04 10-052-05 00103 20110 00053 00016 00076 10-052-11 20273 20283 20293 11-070-03

|

GEAR SECTION HOUSING, with 6" Flange MOTOR M-100 CHAIN COVER M-100, Aluminum, 15-38 Ratio PLUG, Pipe, Oil Fill Hole, 1/2 ", Hex Head MOUNTING PLATE M-100, Steel, 15-38 Ratio EXCENTRIC M-100, 15-38 Ratio CRAB CLAMP, holds Excentric CAP SCREW, Hex Head, 5/16-18 x 1" (Cover Bolt) CAP SCREW, Socket Head, 5/16-18 x 1" (Cover Bolt) CAP SCREW, Hex Head, 3/8" x 3./4" (Plate Cover) WASHER, Lock, 5/16" WASHER, Lock, 3/8" CAP SCREW, Socket Head,5/16-24 x 5/8"w.Wire Hole (Clamp bolt) GASKET M-100, 15-38 Ratio, Cover Seal GASKET M-100, 15-38 Ration, Differential Seal GASKET M-100, 15-38 Ration, Motor Seal CHAIN, 38 Links, 3/8" Pitch

|

1 1 1 1 1 1 2 10 4 6 16 6 2 1 1 1 1

|

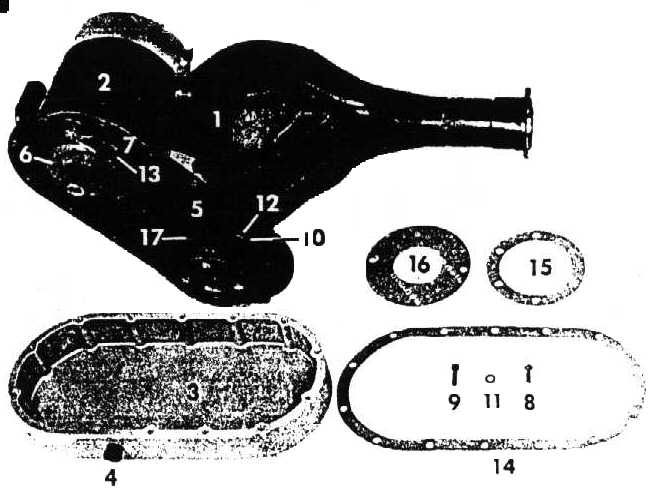

MOTOR FIELD M-200B

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6

7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 |

17-074-00 17-004-02 17-004-03 20123 20010 20024 00056 20038 00135 20134 00015 17-074-13 17-074-14 17-074-15 10040 17-074-17 17-074-18 17-074-19 00233 00035 17-079-02 17-078-00 00106 00006 00365 00215 20243 |

MOTOR FIELD M-200 B, complete with Brake Shoe, less Studs FIELD COIL M-15 FIELD COIL (Pole Piece # 20108) INSULATOR (Pole Piece) CAP SCREW, Socket, Flat Head, 5/16-18 NC x 3/4" WASHER, Fiber, 3/8" I.D. x 1" O.D. WASHER, Brass, 3/8" I.D. STUD, Field Terminal, Brass, 3/8-16 NUT, Hex, Brass, 3/8-16 INSULATOR SLEEVE, 3/8" I.D. x 1/2" O.D. x 1/4" long NUT, Hex, Steel, 3/8-16 BRAKE SHOE M-200 B SPRING, Brake Shoe Return, M-200 B WASHER, Spring Retainer, cupped, 3/4" I.D. x 1-1/2" O.D. COTTER PIN, 1/8" x 1-1/2" BRAKE ARM, Steel, M-200 B, 1/4" x 3/4" x 7" LINK, Brake Arm, Steel, 3/16" x 1/2" x 1-1/2" CLEVIS, Anchor Bold, Steel, M-200 B, 3/8" x 1-1/2" CAP SCREW, 1/4-20 x 1" NUT, Flexlock, 1/4-20 STUD, Mounting, 3/8-16 x 11-3/8" T.B.E., Nut locked on end STUD, Motor Bolt, 1/4-20 x 10-1/2" T.B.E. Nut locked on end WASHER, Flat Cut, 3/8" WASHER, Flat Cut, 5/16" NUT, Slotted, 3/8-16 NUT, Flexlock, 1/4-20, thin type ROLL PIN, "Sel-lok" Carb. Steel, 3/16" x 3/4" |

4 4 4 8 4 4 2 2 2 2 1 1 1 1 1 2 1 3 3 2 1 2 2 2 1 1 |

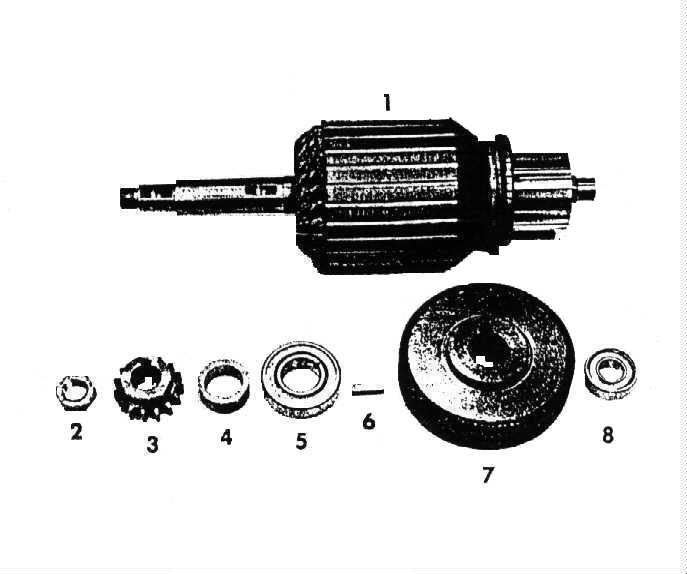

ARMATURE M-200B

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6 7

8 |

17-076-00 00165 11-000-01 17-076-01 20013 20000 17-076-02

20053 |

ARMATURE, M-200 B, with 3/4" Gear Seat NUT, Hex, 5/8-18 NF SPROCKET, 15 Tooth, 3/8" Pitch, 3/4" Bore SLEEVE, Spacer, 1" I.D. x 5/8" long (approx.) BEARING # 205 KK, Drive End WOODRUFF KEY, 1/4" x 7/8" BRAKE DRUM, with Lining, M-200 B, 1" I.D. x 4-3/8" O.D. x 1-1/4" thick BEARING # 7016 P, Commutator End |

1 1 1 1 2 1 1 |

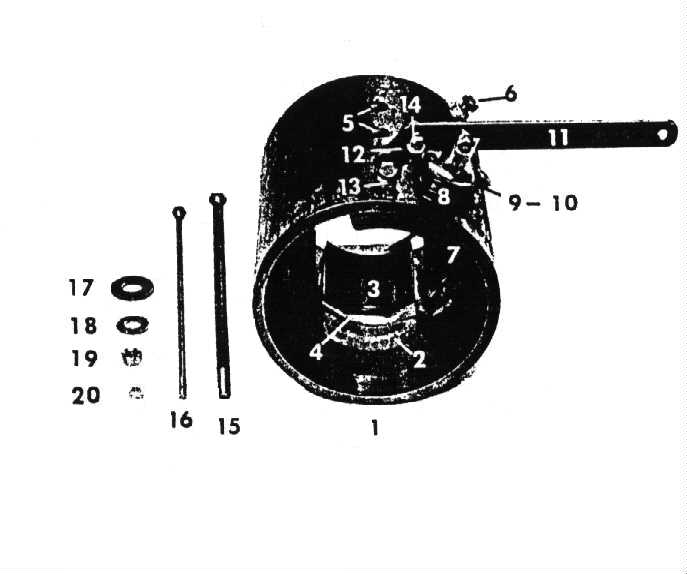

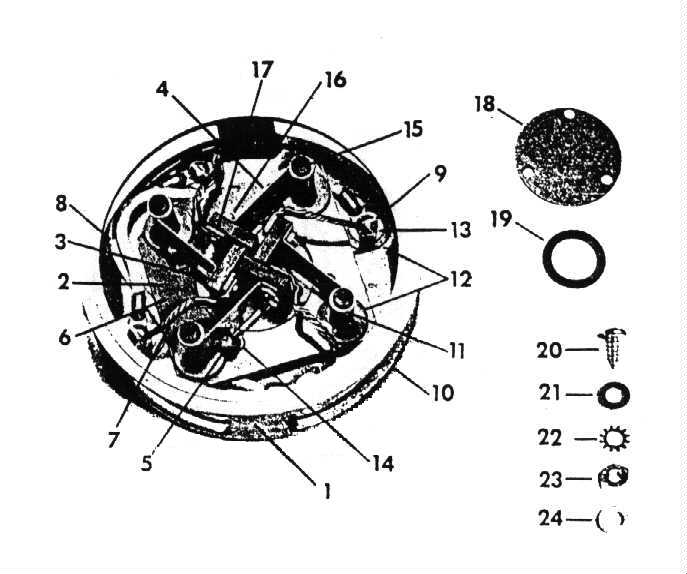

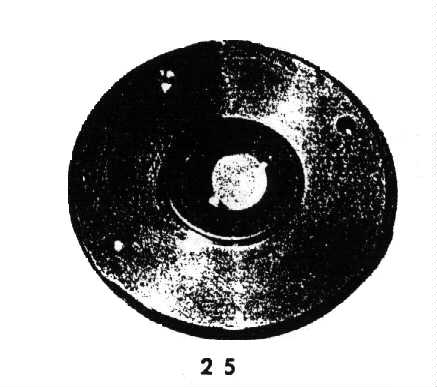

ENDPLATES M-17 and M-100

(used on M-100 and M-200 Motors)

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5

6 7 8 9

10 11 12 13 14 15 16

17 18 19 20 21 22 23 24 25 |

17-052-00 17-003-00 17-052-00 17-003-00 20153 17-003-11 20033 20034 17-003-01 17-003-02 17-002-01 00251 00261 00125 20014 20074 00046 00018 20030 00031 00275 17-003-13 20123 20154 20164 00028 00126 00096 00095 20094 17-055-00 |

END PLATE M-17, with 3 Mounting Holes, complete with Brush Ring and Brushes M-15 END PLATE M-17 only, with 3 Mounting Holes BRUSH RING only, complete with Brushes M-15 BRUSH M-15 BRUSH ARM, with Bushing SPRING INSULATOR BRUSH RING only, Micarta, without Brushes PIG TAIL, Brush JUMPER WIRE, End Plate BOLT, Brass, 1/4-20 x 3/4" BOLT, Brass, 1/4-20 x 1" NUT, Brass, 1/4-20 WASHER, Fibre, 1/4" I.D. x 1/2" O.D. WASHER, Fibre, 1/4" I.D. x 1" O.D. WASHER Brass, 1/4" SCREW, self-tapping, #8 x 1/2" SCREW, Socket Shoulder, 1/4" x 1-1/2" MACHINE SCREW, 6-32 x 5/8" NUT, Hex, 6-32 COPPER PLATE, Brush DISK, Bearing Cover WASHER, Fibre, Endplay, 1/32" thick, as needed WASHER, Fibre, Endplay 1/16" thick, as needed SCREW, self-tapping, #8 x 3/8" WASHER, Steel, # AN 960-10 L (fits item #15) WASHER, Shakeproof #1110-00 (fits item #15) NUT, Hex, 10-24 (fits item #15) INSULATOR SLEEVE, 1/4" I.D. x 3/8" O.D. x 1/8" (fits item #9) END PLATE M-100, Drive End |

1 1 4 4 4 4 1 4 2 2 2 4 4 12 8 2 4 8 8 4 1

3 4 4 4 4 1 |

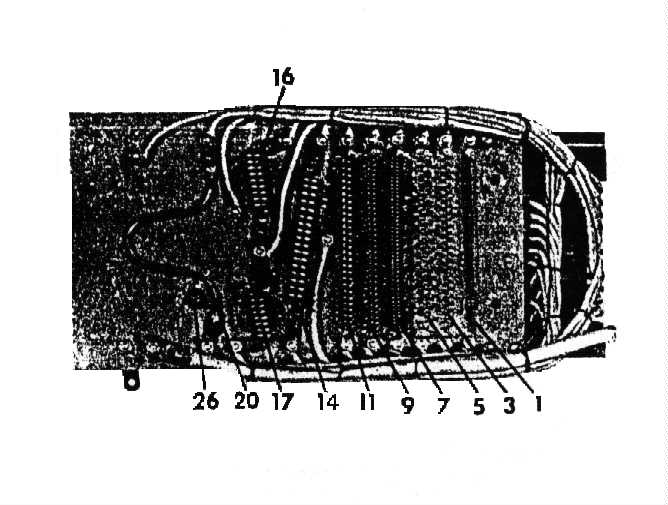

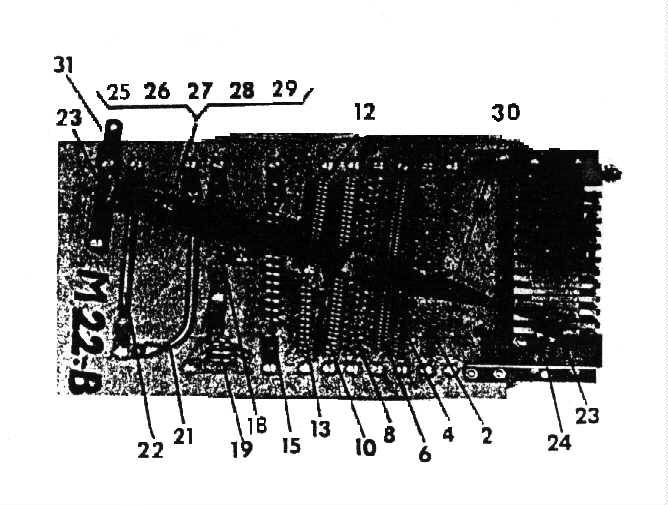

MASTER SWITCH

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

33 34 35 36 37 38 39 40 |

19-030-00 19-023-01 19-023-02 19-023-03 19-023-04 19-023-05 19-023-06 19-023-07 19-023-08 19-023-09 19-023-10 19-023-11 19-023-12 19-023-13 19-023-14 19-023-15 19-023-16 19-023-17 19-023-18 19-023-19 19-023-20 19-023-21 16-023-22 70334 00031 00074 00045 00245 00006 60291 19-025-01 19-000-04 00091 00111 00095 00126 00096 19-028-01 00063 00116 00235 00035 |

MASTER SWITCH M 22-5, Electro-Flo, complete RESISTANCE COIL # 1, Wire Size 22 " " 2, " " 22 " " 3, " " 22 " " 4, " " 22 " " 5, " " 19 " " 6, " " 14 " " 7, " " 14 " " 8, " " 14 " " 9, " " 14 " " 10, " " 11 " " 11, " " 11 " " 12, " " 11 " " 13, " " 11 " " 14, " " 7 " " 15, " " 7 " " 16, " " 7 " " 17, " " 7 " " 18, " " 7 " " 19 " " 7 " " 20 " " 6 Not in coil " " 21, " " 6 " " " " " 22, " " 6 " " " BRUSH # M1 SCREW, machine, 6/32" x 5/8" (Used to bolt Brush to Arm) STUD, 5/16" x 4", threaded both ends (Pivot Bolt for Arm) NUT, Flexlock, 5/16-18 NUT, Square, 5/16-18 WASHER, cut, flat, 5/16 SPRING # A 11225 P ARM, Brush, M 22 CONTACT BAR, copper, 3/16" x 1/2" x 4 1/4", with 3 # 10 holes SCREW, machine, 10-24 x 3/4" SCREW, machine, 10-24 x 1" NUT, Hex, 10-24 SEE NOTE BELOW WASHER, flat, # AN 960-10L WASHER, Shakeproof # 1110-00 ARM, wood (Customer drills Holes to insure fit) CAP SCREW, 1/4-20 x 1 1/4" WASHER, Cut, flat, 1/4" NUT, Square, 1/4-20 NUT, Flexlock, 1/4-20 NOTE: Items 31, 33, 34, 35 are the small bolts and nuts used to Fasten the resistance coils and other hardware to the Switch board. These items are not number in the picture. |

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 4 1 2 1 1 1 1 1

1 2 4 2 2 |

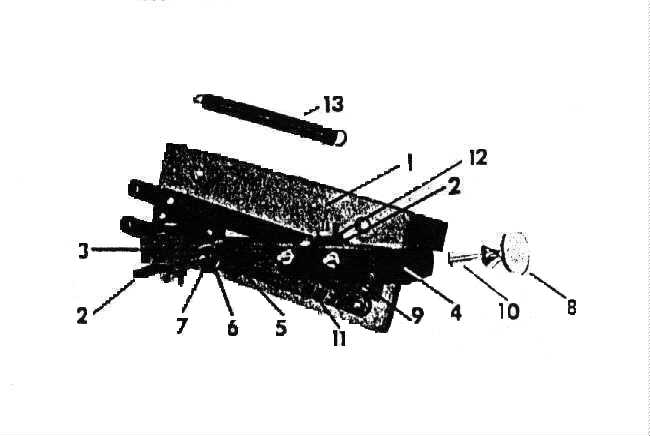

REVERSING SWITCH

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6 7` 8 9 10 11 12 13 |

19-040-00 19-041-00 19-010-04 19-042-01 19-042-03 60251 00116 00045 20203 00121 00081 00095 00096 10086 |

REVERSING SWITCH #425, complete (see Note below) SWITCH PLATE, with copper Bars only "J" BRUSH, Reversing Switch ARM, wood, Reversing Switch ARM EXTENSION # 425 SPRING #29 WASHER, cut, 1/4" NUT, Flexlock, 5/16-18 KNOB, Reversing Switch SCREW, machine, 10-24 x 1 1/4" SCREW, machine, 10-24 x 5/8" NUT, Hex, 10-24 WASHER, Shakeproof, # 1110-00 SPRING # 106 NOTE: Some cars were produced with spring loaded switches and some were not. The switch with a spring has a flat neutral bar. The switch without a spring has a raised neutral bar. When ordering a switch or switch plate, please indicate which type you need. Example: 1 Part No. 19-040-00, Switch, Reversing, # 425, with raised neutral bar. |

1 2 1 1 1 2 1 1 4 1 4 4 1 |

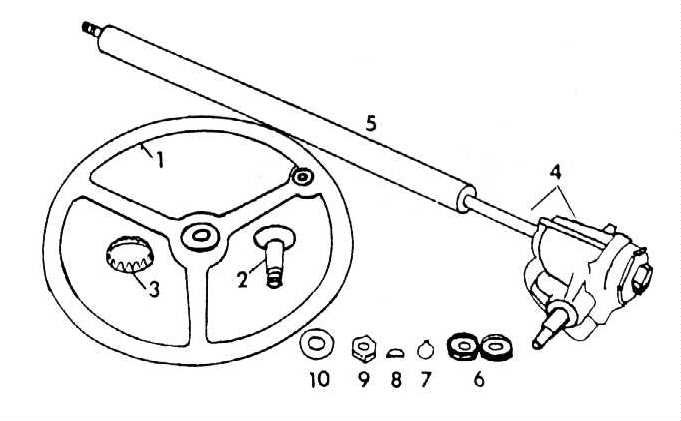

STEERING WHEEL AND SHAFT AND GEAR BOX

120 A

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6 7 8 9 10 |

09-041-01 09-041-02 60301 09-113-01 09-113-02 10047 10918 60361 00115 00186 |

STEERING WHEEL (Sheller) KNOB & BOLT, Steering (Sheller) PLUG, Wheel center, 2" GEAR BOX (64 Chevrolet) with 30-1/8" overall SHAFT, 4 1/2" clear, Shaft in Cover COVER, Steering Shaft, 24" E.M.T. BEARING, Ball, Kilian, 3/4" I.D. SNAP RING, 3/4" WOODRUFF KEY #9, 3/16" x 3/4" NUT, Hex, 3/4-16 WASHER, Flat, 3/4" I.D. |

1 1 1 1 1 2 1 1 1 1 |

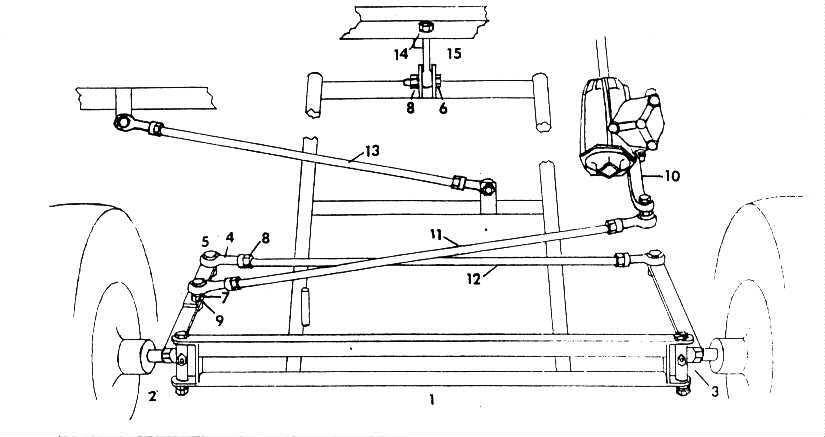

FRONT AXLE & STEERING LINKAGE

120 A

|

Item |

Part No. |

Description |

Quantity Used |

|

1

2

3

4 5 6

7

8 9 10 11 12 13 14 15 |

12-310-00 12-310-01

12-311-00 12-311-01 12-311-02

12-311-03

12-311-04 00405 00223 00115 00176 10128 12-312-00 13213-01 12-312-02

12-312-03

12-312-04 00405 00223 00115 00176 10128 10057 09-055-04 09-115-04

09-055-05

00175 09-056-05 09-113-08 09-114-01 09-115-01 09-116-01 00343 00036 |

AXLE, Front, 120 A, with "A" Frame and Spindles AXLE, Front, 120 A, 27-1/2" from hole to hole, with "A" Frame, without spindles SPINDLE, right, consists of: SPINDLE SLEEVE, 3/4" I.D. x 4-1/2" long ) SPINDLE ARM, 1/4" x 1" x 7-1/2", welded ) replace as to Sleeve ) a AXLE, Cap Screw, 3/4-16 x 5-1/2" long ) unit Welded to sleeve ) SPACER, Axle. 3/4" I.D. x 15/16" long NUT, Hex, slotted, Axle, 3/4-16 NF SPINDLE PIN, Cap Screw, 3/4-16 x 6" NUT, Hex Jam, 3/4" WASHER, Shakeproof, 3/4" GREASE FITTING, Alemite, 1/8" SPINDLE, left, consists of: SPINDLE SLEEVE, 3/4" I.D. x 4-1/2" long ) SPINDLE ARM, 1/4" x 1" x 7-1/2", welded ) replace as to Sleeve ) a AXLE, Cap Screw, 3/4-16 x 5-1/2" long ) unit Welded to sleeve ) SPACER, Axle. 3/4" I.D. x 15/16" long NUT, Hex, slotted, Axle, 3/4-16 NF SPINDLE PIN, Cap Screw, 3/4-16 x 6" NUT, Hex Jam, 3/4" WASHER, Shakeproof, 3/4" GREASE FITTING, Alemite, 1/8" UNIBAL BEARING, 1/2-20 NF spherical rod end CONNECTING BOLT (Drag Link), V-Head, 1/2-20 x 2-1/2" CONNECTING BOLT (Tie Rod - 2, Sway Bar- 2, "A" Frame - 1) V-Head, 1/2-20 x 1-3/4" SPACER (Drag Link Connecting Bolt, tapered and reamed, Machined from Nut, Part # 00225 NUT, Hex Jam, 1/2-20 NF NUT, Hex, 1/2-20, reamed, machined from Part #00225 PITMAN ARM, Steel, 1/2" x 1" x 10", bent DRAG LINK, straight, 1/2" round, 20-1/2" long, T.B.E. TIE ROD, straight, 1/2" round, 22-3/4" long, T.B.E. SWAY BAR, straight, 1/2" round, 13" long, T.B.E. BOLT, Cap Screw, 1/2-20 NF x 1-1/4" WASHER, Lock, 1/2" |

1

1 1 1

1

1 1 1 2 1 1 1 1 1

1

1 1 1 2 1 1 7 2 5

2

13 2 1 1 1 1 1 8 |

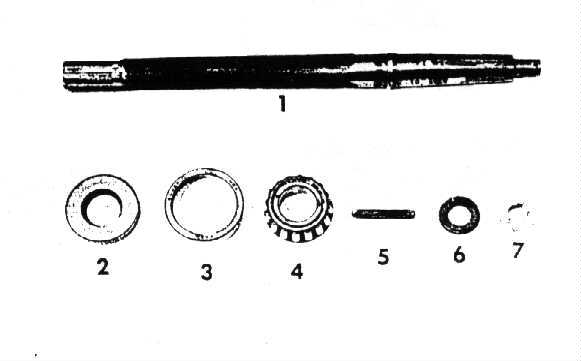

AXLE (PLYMOUTH) TAPERED

42" Differential Width

|

Item |

Part No. |

Description |

Quantity Used |

|

1

2 3 4 5 6 7 |

12-180-01

10438 11018 11008 12-140-04 10-002-07 10-002-06 |

AXLE (Plymouth), Tapered, 17-11/16" long, 10 Spline, used in 42" outside Dimension Wheel Track Units SEAL, inner, Axle RACE # 25821 BEARING # 25877 KEY, 5/16" x 5/16" x 2-1/4" WASHER, Flat, 3/4" I.D. x 1-1/2" O.D. NUT, Hex, Slotted, 3/4-16 NOTE: Beginning May 15, 1964, the above Axles have either 10 or 16 Splines. When ordering a replacement Axle, please state the number of splines. |

1 1 1 1 1 1 |

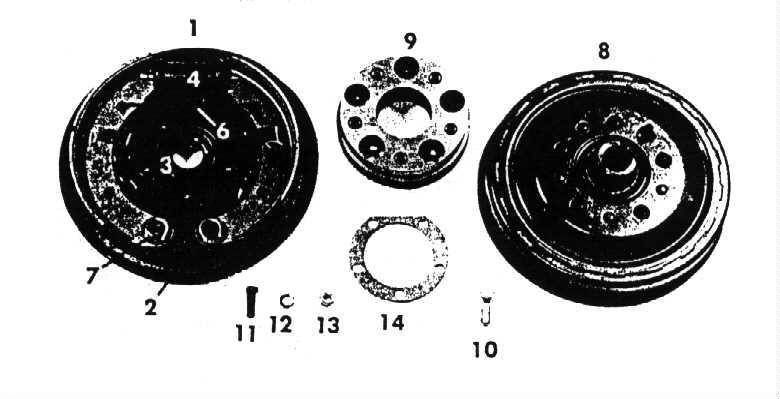

BRAKE (PLYMOUTH) 10 "

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6 7 8

9

10

11 12 13 14 |

16-061-00 16-061-01 10998 11028 16-061-07 16-061-08 11038 16-062-01 16-072-01 16-062-02 16-072-02 10130 10230 10220 00076 00185 10488 10498 10508

|

BRAKE, Backing Plate, with Shoes & Cylinder, Plymouth, 10" BACKING PLATE, only, Plymouth, 10" SEAL, Backing Plate, # T 6241 (or equal) CYLINDER, Wheel, Plymouth, BW 10588 (or equal) BRAKE SHOE, Plymouth, 10", # 12282 SPRING, Brake Shoe, Plymouth CLIP, U Spring BRAKE DRUM, Plymouth, 10", Right Hand BRAKE DRUM, Plymouth, 10", Left Hand SPACER, Wheel, 2" x 6" max. O.D., Right Hand SPACER, Wheel, 2" x 6" max. O.D., Left Hand LUG BOLT, 1/2-20 x 3/4", Right Hand LUG BOLT, 1/2-20 x 3/4", Left Hand MOUNTING BOLT, 3/8-24 x 1-1/8" WASHER, Lock, 3/8" NUT, Hex, 3/8-24 SHIM, Paper, Wheel Bearing Adjustment, .030" thick SHIM, Paper, Wheel Bearing Adjustment, .015" thick SHIM, Paper, Wheel Bearing Adjustment, .005" thick NOTE: On Item 14, Shims, specify amount needed

|

1 1 1 2 1 2 1 1 1 1 10 10 5 5 5 |

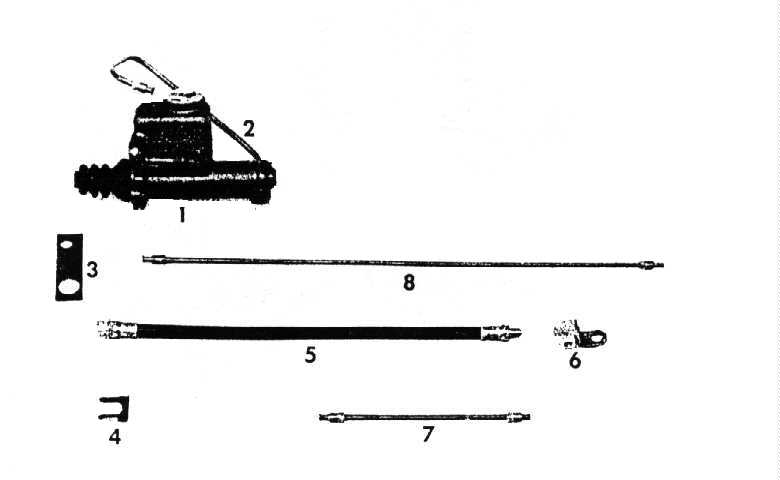

MASTER CYLINDER & BRAKELINES

429 Type

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6 7 8 |

11088 11358 16-094-08 10868 11078 10888 11308 10798 |

MASTER CYLINDER, Wagner # FE 32347 BRAKE LINE, Hydraulic, rigid, 1/4" x 13-1/2" MOUNTING CLIP, Hydraulic Hose HOSE CLIP, # FC 3052 HOSE, Hydraulic, flexible, Wagner # FD\E 16179 "T" FRAME # 5728, with Mounting Clip BRAKE LINE, Hydraulic, rigid, 3/16" x 9" BRAKE LINE, Hydraulic, rigid, 3/16" x 20" |

1 1 1 1 1 1 1 1 |

TIRE, TUBE and WHEEL

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 |

10175 10035 10255 |

TIRE, 5.70/5.00 - 8 x 18, 6 ply, Silent Grip TUBE, 5.70/5.00 x 8x 18 WHEEL, Dico, 5 Hole, 8" x 3-3/4", Demountable |

|

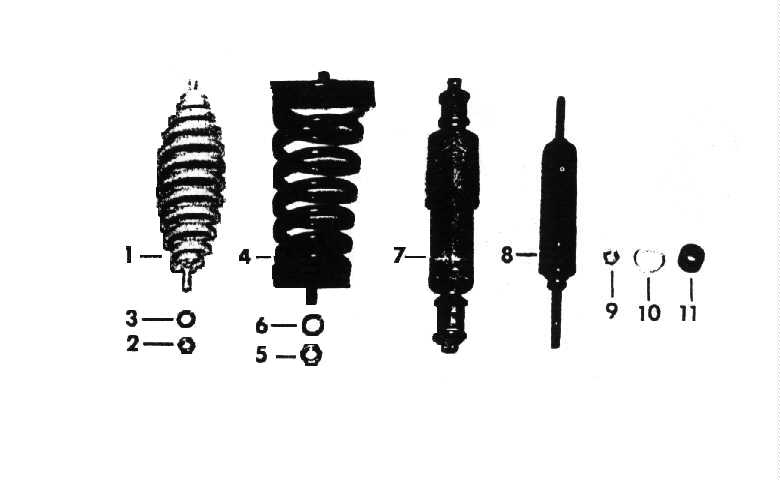

SPRINGS and SHOCK ABSORBERS

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6 7 8 9 10 11 |

8-000-07 00015 00076 4-030-01 00025 00036 10459 10668 00185 10688 10698 |

SPRING, Front Fork NUT, Hex, 3/8-16 (2 per Spring) WASHER, Lock, 3/8" (2 per Spring) SPRING, Rear, Body NUT, Hex, 1/2"-13 (2 per Spring) WASHER, Log, 1/2" (2 per Spring) SHOCK ABSORBER KB 18421 Monroe (used in earlier models) SHOCK ABSORBER # X 600014 (used in later models) NUT, Hex, 3/8-24 (2 per Spring) WASHER, Retaining, # 401008 (4 per shock) BUSHING # 401009 (4 per shock) |

2 4 4 2 4 4 1 2 4 8 8 |

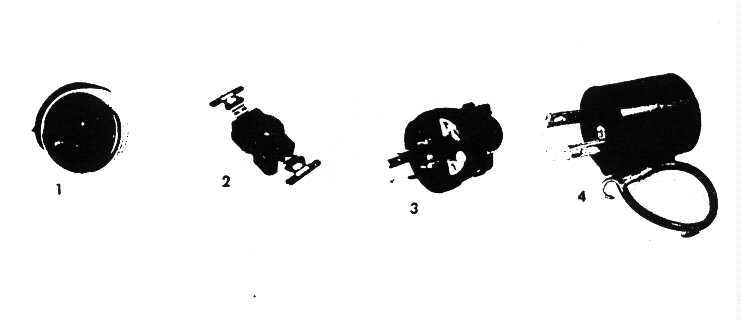

PLUGS and RECEPTACLES

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 |

70144 70184 70124 70034 |

CAP # 1202, polarized RECEPTACLE # 556, polarized CAP # 587, 3 wire ADAPTOR, 3 wire, grounding type |

|

WIRES and TERMINALS

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4

5 6 7 |

70223 70073 70063 70202 70202 70162 70082 70142 |

WIRE # 2 (Order in feet) WIRE # 6 (Order in feet) WIRE # 12 (Order in feet) LUG for # 2 Wire, with 9/32" Hole (Specify Hole Size) LUG for # 2 Wire, with 13/32" Hole (Specify Hole Size) LUG for #6 Wire, with # 10 Hole TERMINAL for # 12 Wire, with # 10 Hole TERMINAL for # 12 Wire, with Hook : |

|

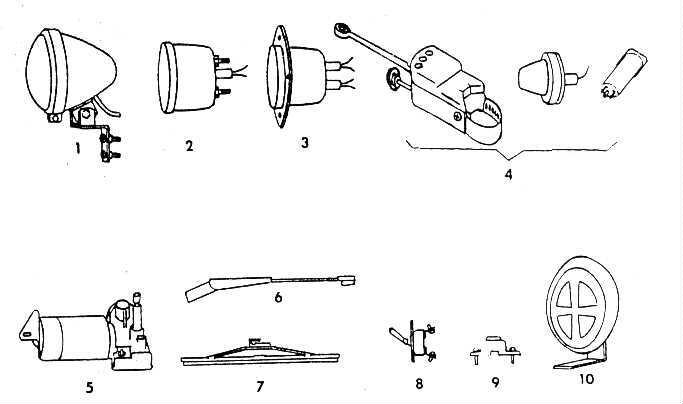

LIGHTS, WINDSHIELD WIPER, HORN

|

Item |

Part No. |

Description |

Quantity Used |

|

1

2 3

4

5 6 7 8 9 10

|

31-011-00 80189 80299 70174 31-012-00 31-013-00 80239 80289 70274 60011

60341 60441 60481 70464 70114 60141 7---3 |

HEADLIGHT, DoRay, 36 volt LENS, DoRay # 511 GASKET, Lens, DoRay BULB, GE 1150, 44 volt, 21 C.P. TAIL & STOP LIGHT, Grote, Studmount, 36 volt TAIL & STOP LIGHT, Grote, Flushmount, 36 volt LENS, Grote 218 GASKET, Grote Lens BULB, GE 110, 44 volt TURN LIGHTS, 12 volt Switch, 4 Lights & Flasher, or Separate # 730 Switch, # 975 Beehive Light (red or clear) # 550 12 volt Flasher WINDSHIELD WIPER MOTOR # WWF 32A13-210S, 36 volt WIPER ARM # LE 726 WIPER BLADE # TAU, 10" SWITCH, Toggle, S.P.S.T. HORN BUTTON # 3042 HORN, 12 volt WIRE # 16 TFF, state color |

|

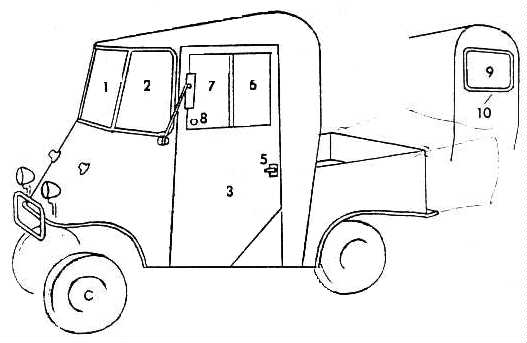

CAB DOORS & WINDOWS, 120A

|

Item |

Part No. |

Description |

Quantity Used |

|

1 2 3 4 5 6

7

8 9 10 |

28-000-01 28-000-02 27-041-00 27-042-00 20443 28-020-01

28-020-02

20203 28-010-00 60186 |

GLASS, Windshield, Center Section, 18=1/2" x 23" CORNER SECTION, Windshield, Pyrolin, 15-1/2" x 19", trim to fit DOOR, Metal; left side, cutout for 2 piece Window DOOR, Metal, right side, cutout for 2 piece Window DOOR HANDLE DOOR GLASS, Stationary Section, Plexiglass, 10-5/8"x 17-3/4", square sides DOOR GLASS, Sliding Section, Plexiglass, 10" Top, 11-1/2" Bottom x 17=3/4" KNOB, Chrome REAR WINDOW, Plexiglass, 1/8" x 9-1/2" x 31-1/2" WINDSHIELD INSTALLING EXTRUSION # AS 892 |

1 2 1 1 2 2

2

2 1

|

Return to Econogics Home Page

Return to Econogics EV Index Page

This Web site created, maintained and sponsored by Econogics, Inc.

All material on this Web site is copyrighted by Econogics, Inc. (unless otherwise noted).

Comments to: Webmaster are welcomed.